Loading... Please wait...

Loading... Please wait...PANEL CUTTING SERVICE!

Posted on October 15, 2016

This post was last updated on 06-28-2018

We now offer panel cutting to your specifications for sheets of pre-laminated wood and composite material - No More Freight Costs For Small Quantities Of Full Sheets!

2 SHEET MAXIMUM! — 3 SHEETS OR MORE STILL SHIPS MORE ECONOMICALLY IN FULL SHEETS ON A PALLET VIA FREIGHT CARRIER.

Previously if you wanted pre-laminated wood and composite sheets included in your order, then the order had to ship palletized via freight carrier (because of the full-size sheets) which could run $175+ depending on your zip code and physical location type (almost always over $200+ for residential locations). This is fine for larger orders when someone is building multiple cases and the freight cost spread over multiple cases was cost effective, but not at all economical for those of you building one case utilizing one sheet of wall material. So, you were forced to go through that pain-in-the-ass process of self-lamination . . . well not anymore if you don't want to!

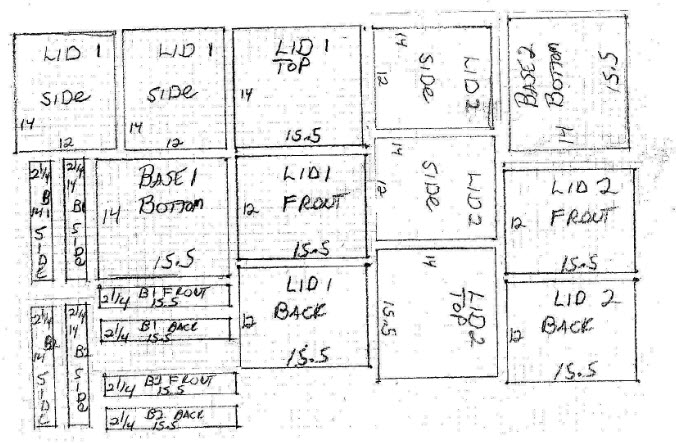

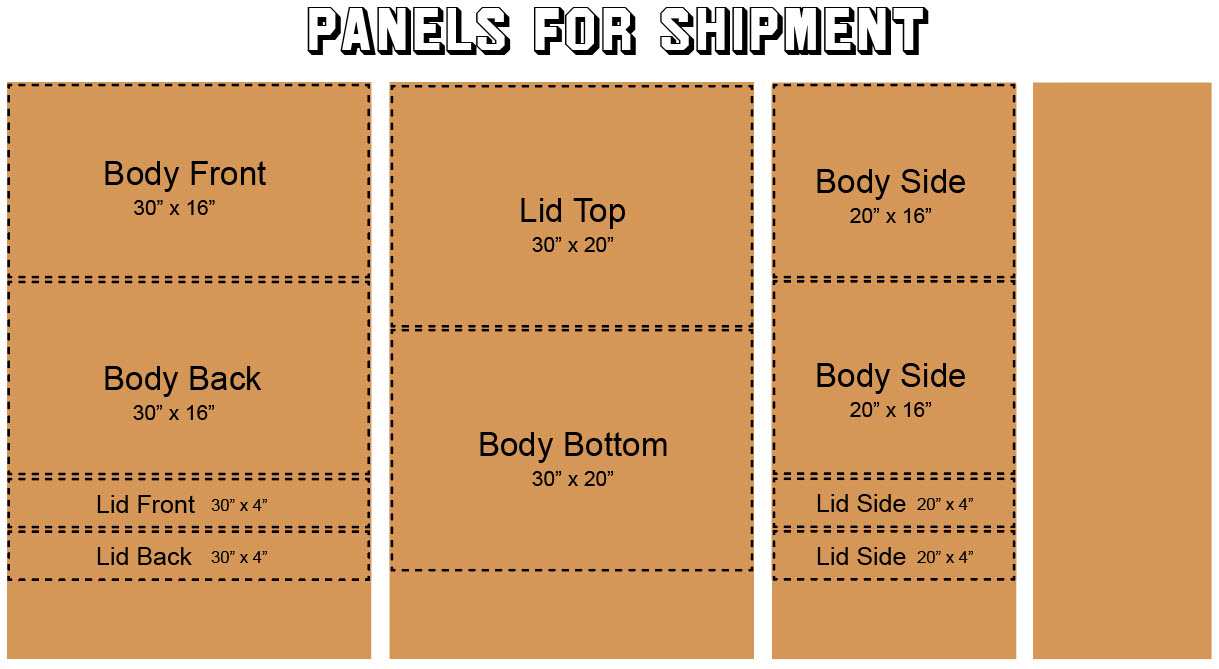

Now you can specify how you'd like your wall panel sheets cut so that they can qualify for ground shipping. This does not mean that we are going to cut every panel to size for your project, such as with this particular cut sheet that was sent to us:

WE WOULD NOT CUT UP A PANEL AS REQUESTED ABOVE

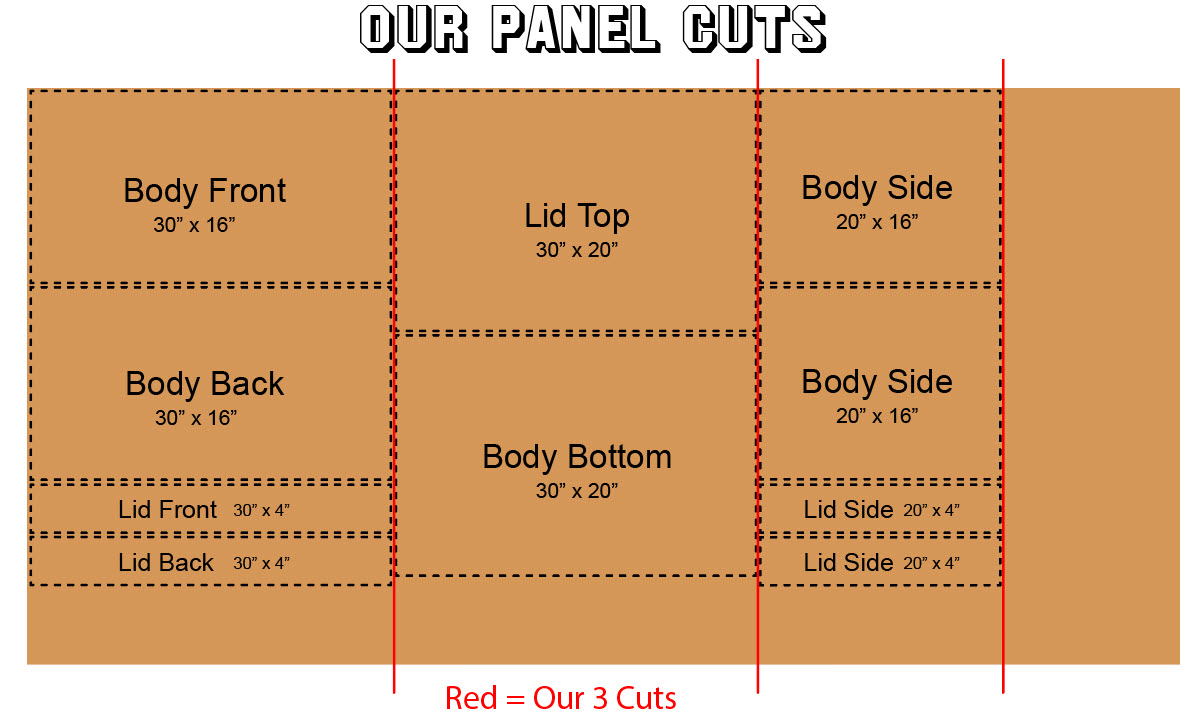

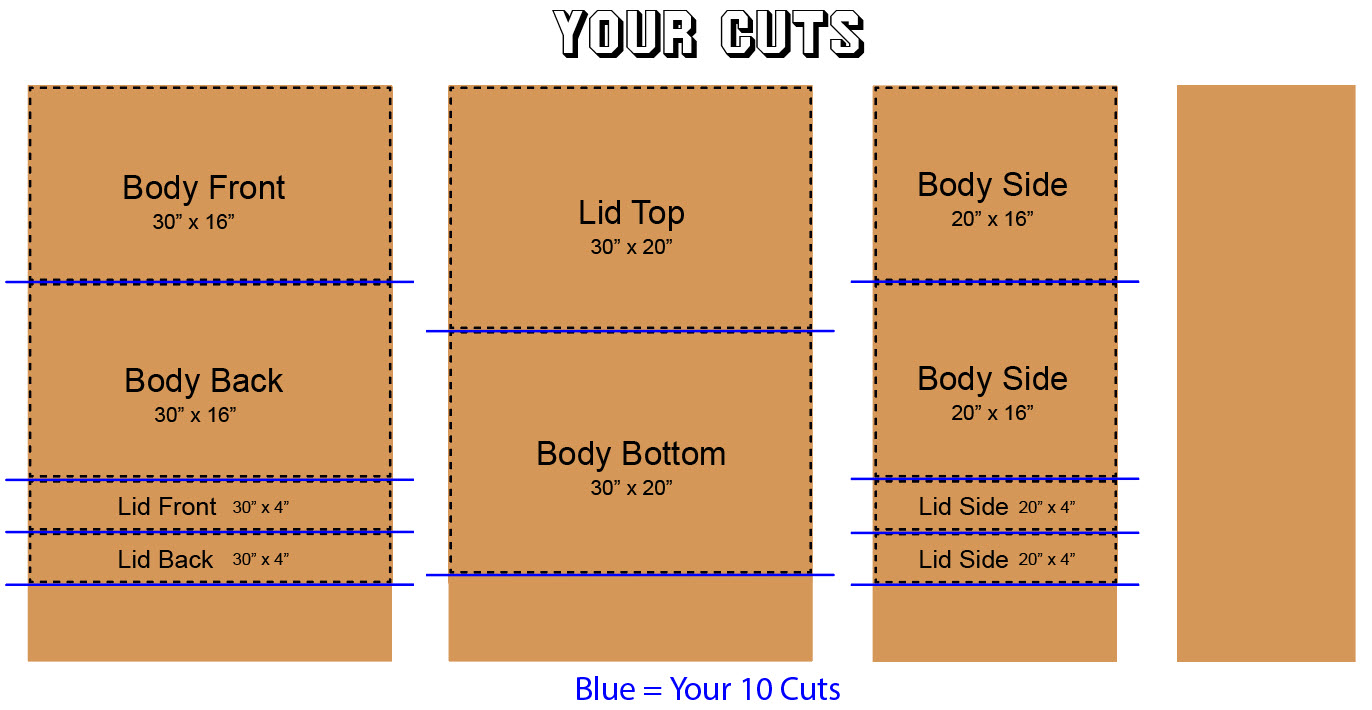

The key is to keep your cuts so that no panel dimension is over 48", with 36"- 40" being optimal, and lay the panels out in such a way that we can make a few straight cuts to get that 4 x 8 sheet down to a manageable and affordable ground shipping size when packaged. For example, simply cutting the sheet in half for two 48" x 48" pieces will not work as UPS's crazy dimensional weight policy for that size panel will defeat the whole purpose of cutting for ground shipping. Also keep in mind that we can ship panels with a package dimension over 36", but be prepared to pay $15 - $30 more for dimensions over 40" depending on the actual dimensions and your shipping zip code (still better than a $174 - $220 freight shipping charge for full sheets, but still a substantial expense).

If you have a case with larger dimensions, then purchasing your own local plywood and laminating it with our ABS Plastic sheet will still be the cheaper alternative. And if you are building a really large case, or multiple cases, that require 3 or more sheets of plywood, then you might want to consider having the full sheets freight shipped with all of your other parts & materials, as this would then be the more economical option when you spread that freight cost over an entire project.

Here are some important rules of thumb to maximize your savings when planning your cuts:

1. Smart panel layouts save money (smaller package dimensions = less shipping cost)

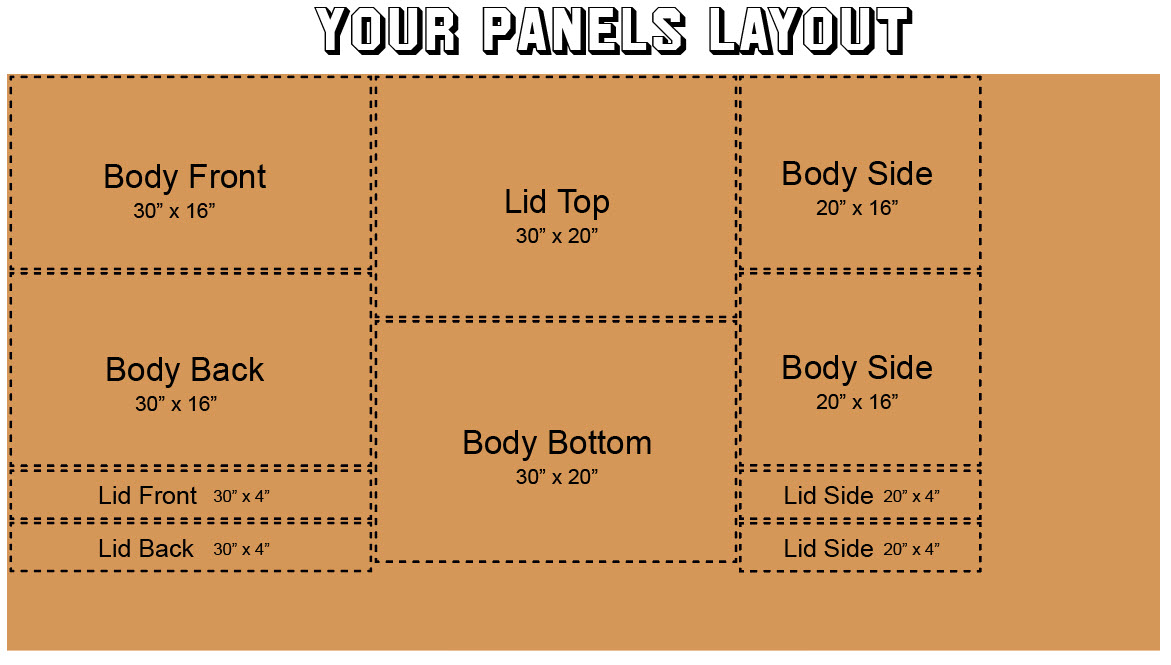

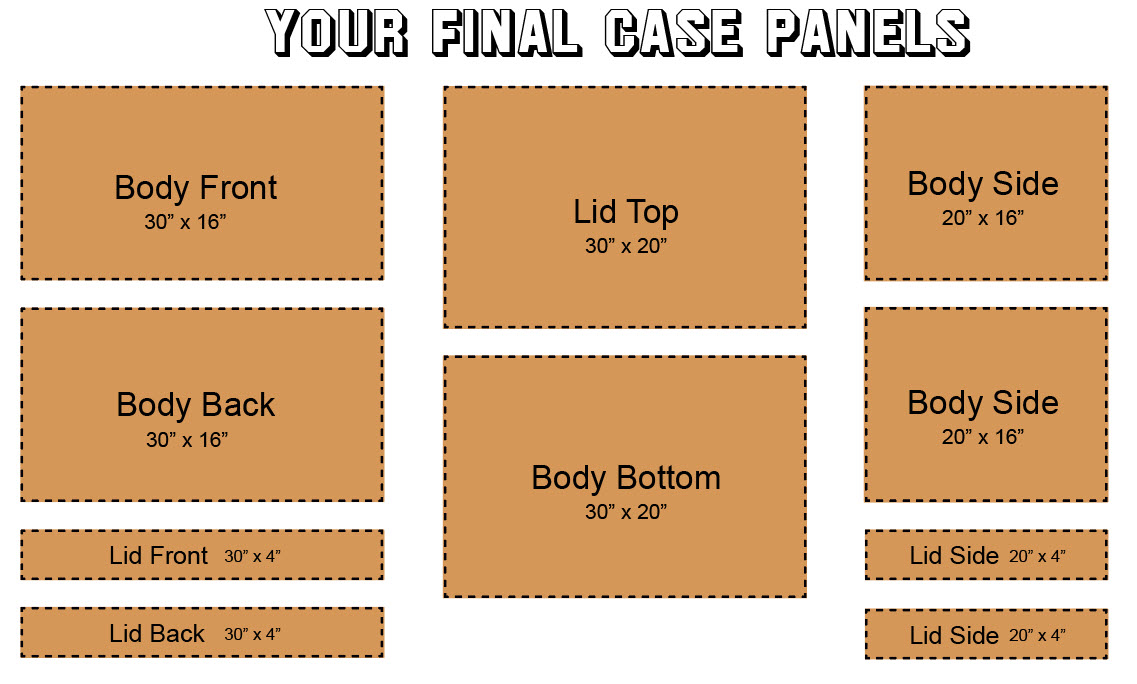

Effective layout for your panel cuts helps us make the best cuts to save you money, as shown in our graphics below.

2. Leave the final smaller cutting for yourself

Most times the cuts that we make to qualify it for affordable ground shipping will do the trick. This is the soul purpose of us cutting up a 4 x 8 sheet for you. Anything beyond that just adds extra cut costs for you that don't translate into additional shipping cost reduction simply because the weight of the package is the governing factor in cost at that point. We will not be doing jig saw puzzle cuts as seen above.

3. Leave any waste out of your shipment if possible (less weight = less shipping cost)

Unless you need the waste (scrap pieces) for some good reason, having it shipped with your order is not cost effective from a shipping cost standpoint. The extra shipping cost for that weight will cost you considerably more than few dollars that you lose from shit-canning the waste. Trying to set up your cut layout so that we can leave waste behind will always help with shipping cost.

See the flow chart example below regarding a well-planned sample panel cutting process for a 30" x 20" x 20" trunk-style case. After the flow chart example we'll explain how the process works, tips on how to prepare your panel cut sheet, and how to get yourself set up for the panel cutting process:

How The Process Works

REMINDER — 2 SHEET MAXIMUM!

1. Determine the dimensions of your case panels as seen in the example above (Download & print the appropriate cut sheet layout packet below and follow the directions if this helps).

2. Create the cut sheet layout document from one of our packets below, or make your own cut instructions drawing.

3. Place your order and in the Order Comments box put "see cut sheet", or type in your simple cut instructions if a drawing is not required.

4. Email the document that you created in step #2, or your own cut drawing, to sales@diyroadcases.com and reference your order number in the email. Tell us any preferences that you may have regarding the cuts. Some people want all of their panels cut so that they don't have to mess with it. Some only want us to make just enough cuts to qualify for ground shipping.

NOTE: When you perform your panel layout for your cuts, make sure and keep in mind that you lose 1/8" for blade width on each cut.

It's that simple. Once we have verified the cuts and done a packaging configuration, we will provide you with a payment link for the $2.50 per cut charges and any additional shipping cost to what you paid at the time of the order.

Plywood Cut Sheet Packet | Ultra Lite Flite™ Cut Sheet Packet | Super Flite™ Cut Sheet Packet

* Reminder: If you are not looking for specific panel cuts and just want 2 - 4 simple cuts to facilitate ground shipping, you can just describe your cut directions/dimensions in the Order Comments. We will contact you if we have any questions.